Calibration Certificate requirements

The calibration certificate contains vital evidence of the integrity of test equipment and the validity of a calibration. This is despite the fact that the requirement to calibrate equipment is considered by some to be simply a ‘necessary evil’ to attain quality. Companies in a variety of worldwide industries spend a huge amount of money annually to calibrate their instrumentation. Yet the tangible evidence of what has been obtained in return for this investment generally receives scant attention. Except for a quick glance before consignment to the filing cabinet where it lies awaiting retrieval in the unlikely event of scrutiny during an audit, the calibration record is hardly reviewed after its receipt. One point is the mistaken assumption that all calibrations are alike, but another is a lack of knowledge about what to look for and its significance.

Why is Calibration necessary?

As components become old and equipment faces changes in temperature or sustains mechanical stress, critical performance gradually degrades. This is called drift and, when it happens, test results achieved using measurement equipment become unreliable and both design and production quality suffer. Whilst drift cannot get rid of, it can be detected and contained through the process of calibration.

Calibration is defined as a performance comparison against a standard of known accuracy.

It may just involve the determination of the deviation from nominal or include correction (adjustment) to lessen the observed error. Properly calibrated equipment fosters confidence that manufactured products and support services meet their specifications.

Calibration:

1. Increases production yields,

2. Optimizes resources,

3. Assures consistency,

4. Is fundamental to compliance with international, regulatory, or industry-sector-specific standards that need measurements to be ‘traceable to national standards and, in doing so,

5. Ensures measurements (and perhaps products) are consistent with those made elsewhere.

Traceability:

A hierarchical relationship is attained by calibrating equipment through the use of standards of better accuracy.

It could be illustrated like this:

National Standard……………………… Accurate to 0.02 %

Calibration Laboratory………………………………….0.13 %

Production Equipment…..…………………………..0.6 %

Manufactured Product……………………………….…8 %

Calibrations are required to be done on a planned, periodic basis with evidence of the comparison results maintained. This record must include identification of the specific standards used (which must be within their assigned calibration interval) and some means of knowing the method used and other test conditions.

Types of calibration certificate.

When calibration is performed, the certificate or report is the end product. It represents the only concrete evidence of the service that the purchaser can link to the expenditure. Its importance is obvious for that reason alone. Not only does it show the results achieved across the scope of testing, it is also a key means of judging the quality of the calibration provider’s service.

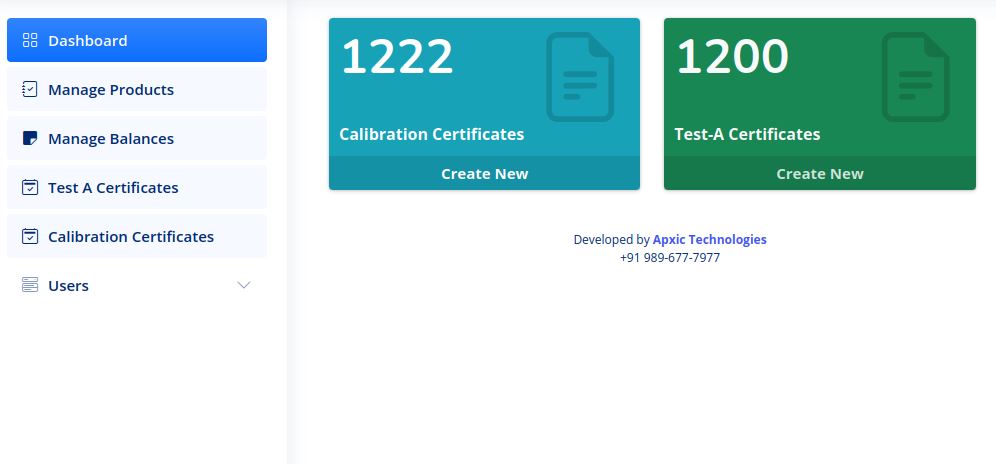

Benefits of Apxic Calibration Certificate software are:-

1. Multiple user logins can be created according to the role of company staff.

2. User-friendly interface and easy to manage.

3. Daily generated certificated counts will be visible right on the dashboard.

4. Create an infinite number of certificates having client and product details.

5. You can edit certificate details anytime from mobile or desktop from anywhere.

6. An unlimited number of lab equipment details can be added or modified like name, measurement, weight, volume, photo, ltr, least count, etc as per your requirement.

7. You can add multiple product types and manage them easily.

8. Every certificate has its unique QR code and link. You can easily scan QR code from mobile & which contains all details of the certificate generated.

9. You can use QR on packages of lab equipment for a better client experience.

10. Easily maintain your records of client details, lab equipment details, and many more.

11. Certificate details can be verified online by certificate number on the website.

12. You can add a digital signature and stamp on the certificate.

13. You can deactivate the account of any staff employee on run time so that they cannot log in to the software.

Recent Comments